ASTRONAUT'S COAT RACK

ENGINEERING DESIGN 1, FALL 2018

Final prototype on testing stand. Had a mass of 1.1 grams and successfully held the 25 lb weight without deflection.

The objective of this project was to design a laser cut acrylic bracket to sustain a weight in space. The bracket must attach to a pegboard while avoiding any overlap with the “forbidden zone” and support a 25 pound force without breaking. Part geometry was designed so as to minimize mass within constraints on loading and manufacturing. In this project I utilized SolidWorks simulations and iterative design process to find the optimum design. This design features a V-shaped acrylic bracket with filleted holes on the top members for mounting. The suit clip sits in the middle of the V, where there is a circular indent that matches the curvature of the peg.

Isometric screenshot of the final design.

Results of SolidWorks stress analysis on the final design. Stress was maximized at the side of the supporting loops with a factor of safety of 1.6.

Testing Rig

Model of the testing stand. The part cannot overlap with the “forbidden zone,” shown in red. The bracket can overlap with the green areas, but it cannot be used for support.

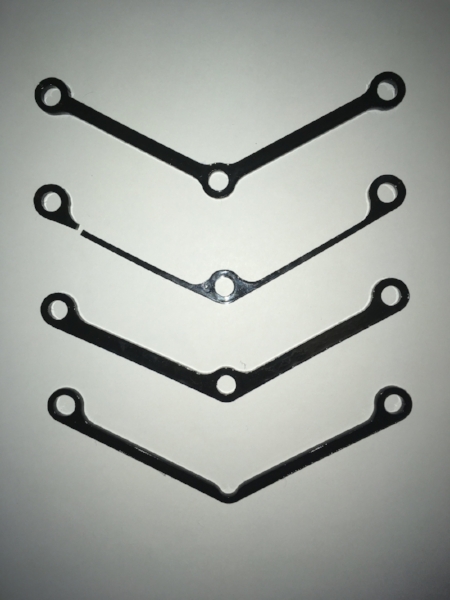

Prototypes

Progression of prototypes (from top to bottom) for the initial design review. The bracket used for the first testing day had a mass of 2.5 grams.

Progression of prototypes after the initial design review. Design was refined to minimize stress concentrations and reduce mass. Notable changes include shortening the bracket in order to decrease internal stresses and minimize weight.