Switch joy-con Grip

DIY Design and Fabrication, Spring 2020

The purpose of this project was to explore and design a new, ergonomic handle for an existing product. I chose to create a grip for a Nintendo switch joy-con controller. The controllers can be detached to play in a variety of different ways. The user can play with either both joy-cons, similar to a traditional controller, or a single joy-con turned horizontally. The system is sold with a grip for two controllers; however, a single joy-con is difficult to grip and is hard to reach all the buttons and lacks the ergonomic grip of a traditional controller.

Using a single joy-con horizontally.

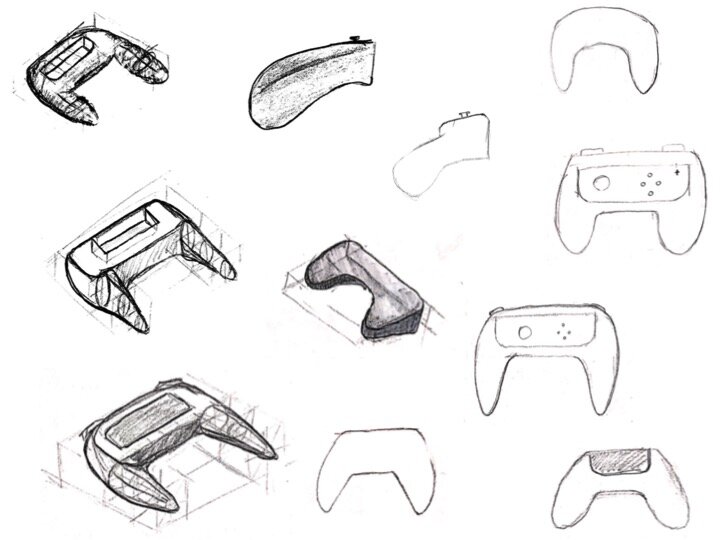

Sketches of initial design concepts. Modeled after Xbox, GameCube, and PS4 controllers.

Initial Prototyping

Initial wood support structure. I originally intended to 3D print a railing for the joy-con to slide into

Application of clay onto support structure.

Finished model. After experimenting with joy-con placement, I decided to 3D print a new support structure so the controller could sit flush with the surface.

Wooden support for second iteration. Since the first 3D printed prototype did not fit correctly over the joy-con, I attempted to mold over the wood while reprinting.

Without the support of the 3D printed piece, the wooden support snapped.

Final Model

Support structure. 3D printed ABS forms a snap fit around the joy-con, with laser-cut acrylic.

Model after smoothing with tools.

Finished prototype.

Model after initial layer of clay.

Model after smoothing with damp sponge.

Finished prototype in use.

Side by side comparison of original joy-con and ergonomic grip.

Note: Originally, the intent of this project was to create a silicon mold of my clay model to cast plastic parts. However, due to the COVID-19 crisis, in-person classes were canceled and the project was cut short.